strain gauge torsion test|shear strain torsion test : agencies 13. Test Procedure • Using vernier caliper, measure the diameter of the specimen • Calculate J (torsional stiffness) • Using a same weight, find the colors (gauges) with same sign (which two are copressive and which two are . [NAMJIN] Eu estive tentando suportar algumas coisas por muito tempo, como depender da família do meu melhor amigo para sobreviver, ter que aguentar pessoas de .

{plog:ftitle_list}

web25 de ago. de 2023 · https://youtu.be/rlrJifPizh0 Cassino que eu indicohttps://youtu.be/hnHTe-9dy-w Este app paga mesmo

V-shaped strain gauges (e.g. XY4) have 2 measuring grids arranged at a 90° degree offset from each other. Typical applications for these strain gauges include measurements on torsion bars and determining shear stresses as they occur .

A grid configuration for the strain sensitive element is used to allow higher values of gage resistance while maintaining short gage lengths. Gage resistance values range from 30 to . 13. Test Procedure • Using vernier caliper, measure the diameter of the specimen • Calculate J (torsional stiffness) • Using a same weight, find the colors (gauges) with same sign (which two are copressive and which two are .An unmounted resistive foil strain gauge. A strain gauge takes advantage of the physical property of electrical conductance and its dependence on the conductor's geometry. When an electrical conductor is stretched within the limits of its elasticity such that it does not break or permanently deform, it will become narrower and longer, which increases its electrical .

However, the specimen sees the torsional wave before the strain gauges attached to the bar, which means that there is a time delay to obtain the torque measurement on the specimen. . Sun FL, Zhang GQ (2009) Comparing drop impact test method using strain gauge measurements. Microelectron Reliab 49(9–11):1299–1303. Article Google Scholar

STRAIN When a force is applied to a body, the body deforms. In the general case, this deformation is called strain. In this application note, we will be more specific and define the term STRAIN to mean deformation per unit length or fractional change in length and give it the symbol, . See Figure 1. This is the strain that we typically measure .A strain gauge includes a strain-sensitive material and can be the active element in a transducer or attached directly to the device under test [2]. A bonded strain gauge. The bonded metallic strain gauge is a popular choice for stress analysis because of its versatility.In a strain gauge test system, it is possible to see how much strain is applied to different parts under different mechanical stresses. The digital strain displayer could automatically calculate how much voltage and strain are presented and shows the user as a microstrain. . Two special torsion strain gauges measure the torsional shear strain .

Therefore, if we replace R4 in Figure 3 with an active strain gauge, any changes in the strain gauge resistance will unbalance the bridge and produce a nonzero output voltage. If the nominal resistance of the strain gauge is designated as RG, then the strain-induced change in resistance, ∆R, can be expressed as ∆R = RG•GF•ε.What is a Strain Gage? A strain gage works to measure the amount of strain on a given object. At its most basic form, a strain gage converts a change in dimension to a change in electrical resistance. The ratio of mechanical strain to electrical resistance is what is known as the Gage Factor, and is specific to the type/lot of strain gage used.

See Torsion and Shear Strain Gauges. HBM Strain Gauges for High Temps & Alternating Load Resistance; . Go to the site > HBM Strain Gauges for High Temps & Alternating Load Resistance Shear, 1.5 mm Grid Length, 1.5 mm Grid Width. 0.0 (0) Click and hold to zoom. Data Sheet (PDF) 8.65 . (Test to Failure): 10 7 cycles at 2000 µm/m 10 6 .

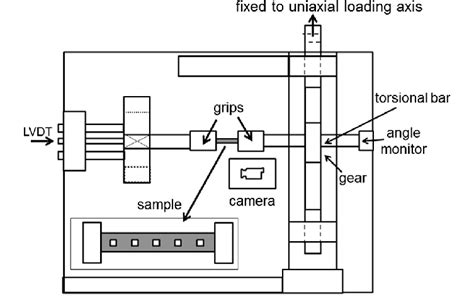

For instance, this situation occurs in transducers or with test objects performing similar functions. In experimental tests, this is hardly ever the case and usually only some of the bridge arms contain active strain gauges, the remainder consisting of bridge completion resistors. . Measurement of torsion strain: Full bridge Four strain .Torsion Test 2 รูปที่ 1 ความเสียหายจากผลของแรงบิด (ซ าย) เพลารถยนต (ขวา) เพลาเจาะ . แรงบิด ประกอบด วยอุปกรณ 2 ส วนใหญ คือ ชุด Strain gage load cell และชุด Bridge Test & Inspection. Test & Inspection. Handheld Meters. Handheld Meters. Wind Tunnels. . See Torsion and Shear Strain Gauges. Shear Strain Gauges with Transducer Quality; . Stay here. Go to the site > Shear Strain Gauges with Transducer Quality 1.8 mm Grid Length, 5 mm Grid Width 350 Ω Resistance, ST STC Number. 3.0 (2) Click and hold to .An example for a torsion hydraulic actuator test (Figure 2.1) for the medium velocity range is given by Lindholm and Johnson [2], cited in the ASM Handbook vol. 8 by Lindholm et al. [3], with the determination of shear-stress–shear-strain curves of different materials.The failure strain and the strain-hardening coefficient are taken. The specimen used was a tube form with an outer .

The actual arrangement of your strain gauges will determine the type of strain you can measure and the output voltage change. See Figures C through F. For example, if a positive (tensile) strain is applied to gauges 1 and 3, and a negative (compressive) strain to gauges 2 and 4, the total strain would be 4 times the strain on one gauge. See .

torsion test diagram

test specimen and calculating the slope of the shear stress versus shear strain curve. In addition, the torsion test specimen will be twisted to failure in order to determine the shear stress at the . gauge reader has been rotated more than one full rotation, keep record of that. 7. Increase the load in fraction of 100 gm, force from Zero to .

The embedment strain gauge is similar to the arc weldable strain gauge except for the fact that mounting blocks are replaced with stainless steel flanges. EDS-20V-SW/Spot Weldable Strain Gauge In Model EDS-20V-SW spot weldable . Understanding Torsion TestingIn the field of mechanics and materials science, torsion testing is a crucial method for assessing the strength and behavior of materials under twisting forces. This comprehensive guide will provide an in-depth understanding of torsional testing, the machines used, and their applications in evaluating the performance and reliability .Strain gauges are used extensively in sensor systems to detect forces, moments and deformations. The FL 100 experimental unit provides a wide-ranging introduction to the fundamentals of measurement by strain gauges. Three test specimens for tension, bending and torsion are each fitted with four strain gauge measuring points.

A strain gauge is a mechanical device that is regulated ASTM Standard Test Methods of Performance Characteristics of Metallic Bonded Resistance Strain Gauges. Usually, a strain gauge is made of Constantan, a alloy the usually consists of copper and nickel. . Lab 9 Torsion Test - Lab report. 69% (54) 14. Ch 12,13,14,15 16-Ready -2017 Spring .

Students can also connect and compare the performance of quarter, half and full-bridge strain gauge connections for each structure. The bending system uses gauges to measure direct tensile and compression strain. The torsion system shows the use of shear/torque strain gauges. The tension system shows the use of two gauges at right angles in a . Key learnings: Strain Gauge Definition: A strain gauge is a device that measures the deformation (strain) of an object when force is applied, through changes in electrical resistance.; Working Principle: The strain gauge detects minute geometrical changes as resistance changes, which indicate the level of stress on the material.; Bridge Circuit: The . In this video, we are going to discuss about Torsion Bar With Strain Gauge for Torque Measurement.Check this playlist for more videos on this subject:Sensors. When a strain gauge is placed on a test article it is attached in such a way that the strain experienced by the test article is transferred to the gauge. . the types of strain that can be measured (bending, axial, torsion), and ability to compensate for temperature and electromagnetic interference. 8.1 Quarter Bridge

One of the most common examples of torsion in engineering design is the power generated by transmission shafts. We can quickly understand how twist generates power just by doing a simple dimensional analysis.Power is measured in the unit of Watts [W], and 1 W = 1 N m s-1.At the outset of this section, we noted that torque was a twisting couple, which means that it has .What was the effective strain during the torsion test? The only strain induced during the torsion test was the true shear strain γxy ~ . No other strains were present: 0~ = ~ = ~ = ~ = ~ = εx εy εz γyz γzx Substituting these conditions into Eq (8), we find: ε γ~ xy 3 1 = .. during the torsion test the effective strain (ε) equaled the . Test & Inspection. Test & Inspection. Handheld Meters. Handheld Meters. Wind Tunnels. . See Torsion and Shear Strain Gauges. Shear, Full Bridge Strain Gauges with Transducer Quality . Go to the site > Shear, Full Bridge Strain Gauges with Transducer Quality 1.8 mm Grid Length, 5 mm Grid Width 350 Ω Resistance, ST STC Number. 5.0 (2) Click .

Unfortunately, the strain gauge material, as well as the test material it is applied to, will expand or contract in response to changes in temperature. . Bending Beam Strain or Shafts Under Torsion with Gauge Pairs Measuring Equal and Opposite Strains: One Opposite Leg Pair Measures Compression, While Other Opposite Leg Pair Measures. 4:

torque measurement using strain gauge

Play online slots and win big at 775.COM, the best casino site with exciting games and bonuses.

strain gauge torsion test|shear strain torsion test